Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

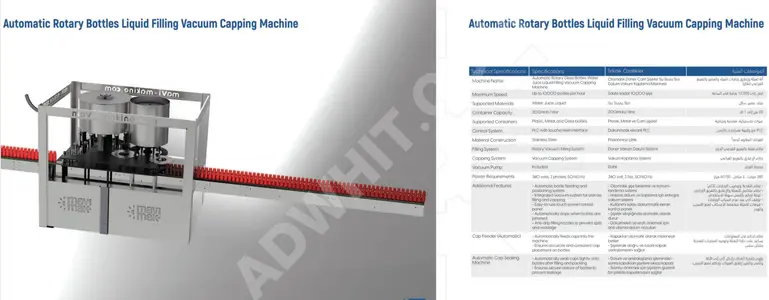

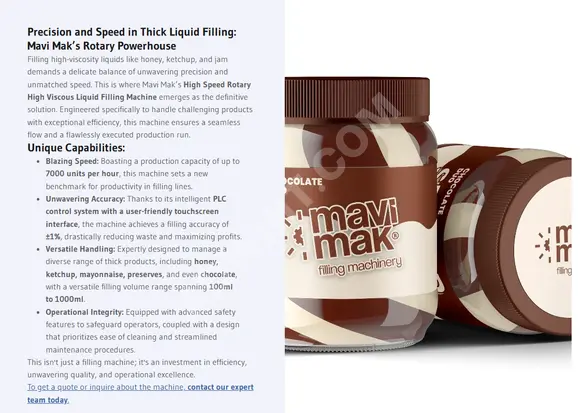

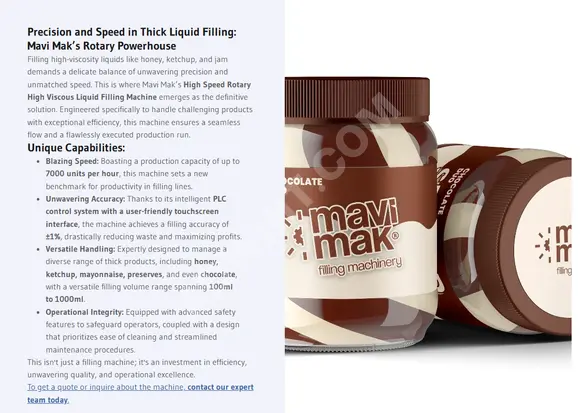

High-speed rotary machine for filling high-viscosity liquids

An advanced machine specially designed for filling high-viscosity products such as: honey, ketchup, mayonnaise, jams, chocolate, and dairy products.

This machine combines super speed, high precision, and flexibility to meet the needs of factories seeking reliable solutions for large-scale production while maintaining product quality.

Thanks to the intelligent PLC control system with a user-friendly touchscreen interface, this machine provides consistent performance that ensures accurate filling, reduces waste, and achieves the highest production efficiency.

⚙️ Technical Specifications

Production Capacity: up to 7000 bottles/hour.

Filling Volume Range: from 100 ml – 1000 ml.

Filling Accuracy: ±1%.

Number of Filling Nozzles: 8 – 12 – 16 – 24 – 32 (as required).

Compatible Package Types: glass – plastic – metal – various packages.

Machine Structure: fully made of stainless steel to ensure hygiene and durability.

Control System: PLC with an interactive, easy-to-operate touchscreen interface.

✅ Additional Features

Suitable for a wide range of high-viscosity products.

High speed ensures continuous mass production.

Hygienic design for easy cleaning and maintenance.

Advanced safety systems protect the operator and increase reliability.

Ideal for food, beverage, and spreadable products factories.