Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

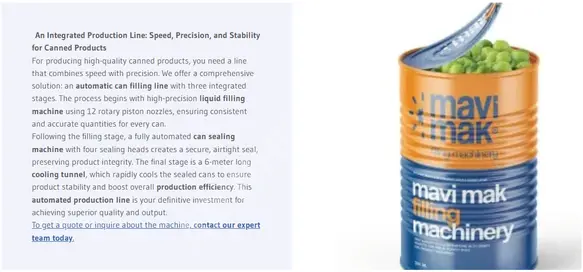

Filling, packaging, and cooling line for metal containers

Integrated automatic production line for filling and preserving food products in metal containers such as cheeses, sauces, jams, and liquid or semi-liquid products.

The line is characterized by high speed and great filling accuracy, in addition to a tight sealing system that preserves product quality and shelf life for long periods, followed by a water cooling tunnel that ensures product stability and increases production efficiency.

This line represents the optimal solution for factories seeking high productivity, superior quality, and reliability in filling and packaging operations.

⚙️ Technical Specifications 1. Filling Machine

Equipped with 12 high-precision rotary piston filling nozzles.

Ensures homogeneous and accurate filling of metal containers.

Suitable for liquid and semi-liquid products such as soft cheeses, sauces, and jams.

2. Sealing Machine

Fully automatic machine equipped with 4 welding heads.

Provides tight, vacuum sealing.

Preserves product quality and prevents leakage or spoilage.

3. Cooling Tunnel

6 meters long, operates with a water cooling system.

Cools the containers quickly after sealing.

Maintains product stability and enhances production efficiency.

✅ Additional Features

Integrated and flexible production line.

Designed from food-grade stainless steel to ensure hygiene.

Easy operation through modern control systems.

Suitable for food, dairy, sauce, and canned food factories.