Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

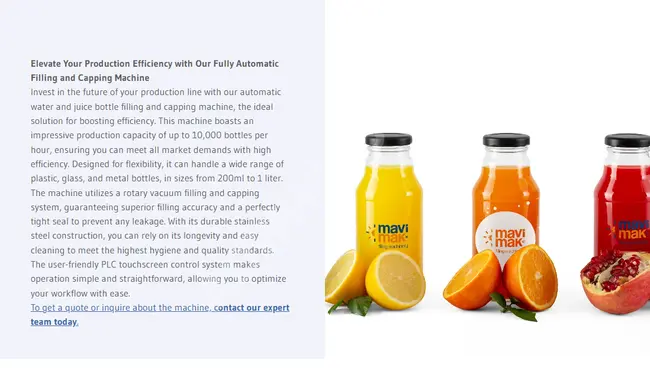

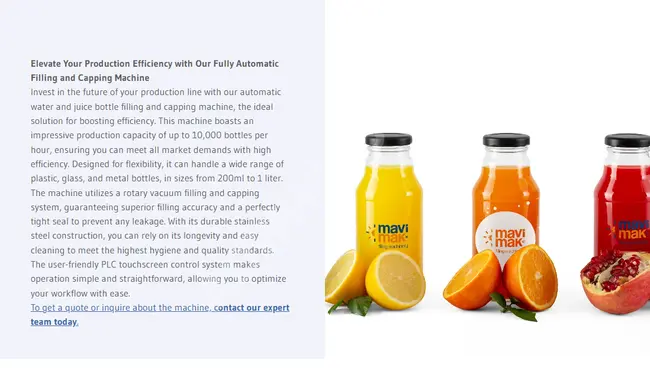

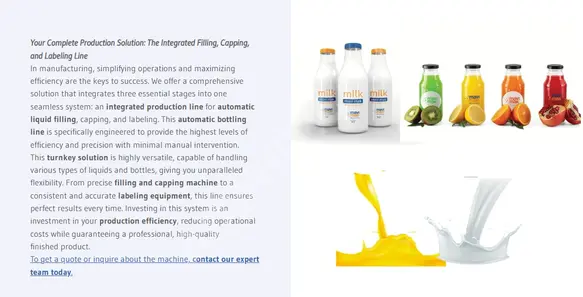

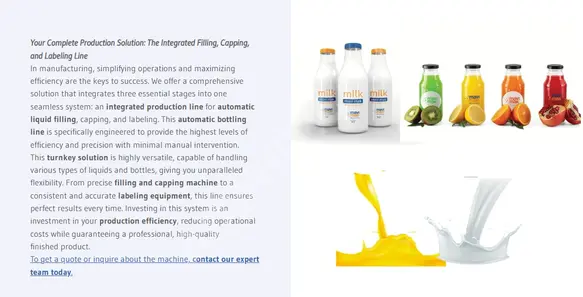

Filling, capping, and labeling line for plastic and glass bottles

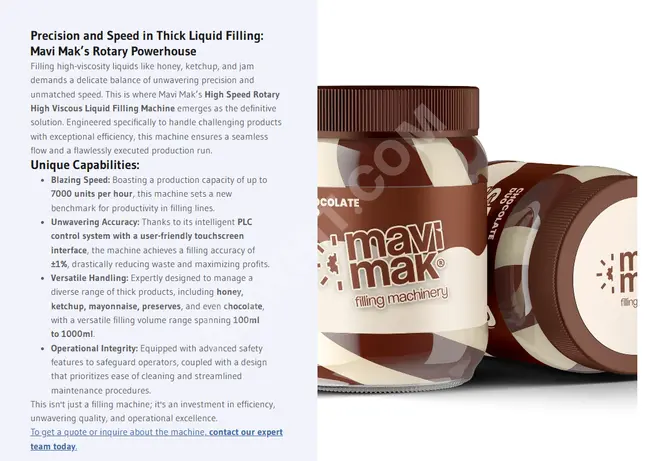

An integrated automatic production line designed for filling liquids into plastic or glass bottles such as natural juices, milk, soft drinks, oils, or liquid chemicals.

The line performs three main operations continuously: precise filling, tightly sealing the caps, and applying identification labels on the bottles.

This system provides a comprehensive solution for factories seeking high efficiency, reduced manual intervention, and ensuring professional quality outputs.

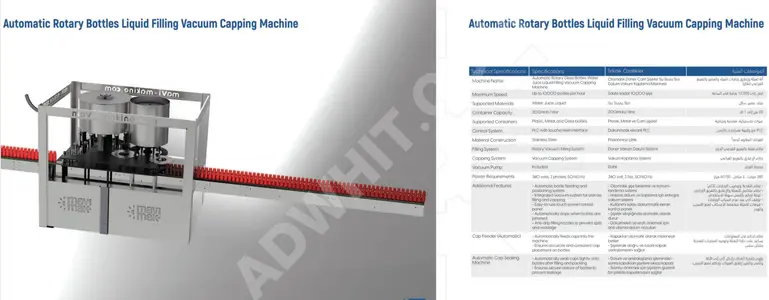

⚙️ Technical Specifications 1. Filling Machine (Bottle Liquid Filling)

Operates fully automatically.

Suitable for filling liquids: water, milk, juice, vegetable oils, or liquid chemical products.

Precise filling system ensures equal quantity in each bottle.

2. Capping Machine

Automatically mounts and tightly seals the caps on bottles.

Prevents leakage and maintains product quality.

3. Labeling Machine

Adds high-precision identification labels to bottles.

Suitable for bottles of different sizes and shapes.

4. Production Line (Machine Line)

An integrated system combining the filling, capping, and packaging operations into one continuous line.

Reduces operational cost and increases production efficiency.

✅ Additional Features

Fully automatic – does not require continuous manual intervention.

Highly flexible to handle different types of bottles and liquids.

Hygienic stainless-steel design to ensure cleanliness and ease of cleaning.

Modern control system ensures easy and reliable operation.

Ideal for food, beverage, and dairy factories.