Property for Sale

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

US Dollar

43.6531

Euro

52.0390

Saudi Riyal

11.6519

Pound Sterling

59.6624

Kuwaiti Dinar

142.5033

United Arab Emirates Dirham

11.8905

Egyptian Pound

0.9328

Iraqi Dinar

0.0333

Bahraini Dinar

115.7999

Qatari Riyal

12.3988

Libyan Dinar

6.9205

Omani Rial

113.5321

Jordanian Dinar

59.2011

Algerian Dinar

0.3373

Moroccan Dirham

4.7913

Syrian Pound

0.3778

R TYPE CUBE SUGAR MACHINE

Ankara / Yenimahalle

Status

New

Advertiser

Owner

Details

Address

Ankara / Yenimahalle / İvedik OSB mah.

Offer number

00465589

Offer date

2026/02/10

Communication Languages

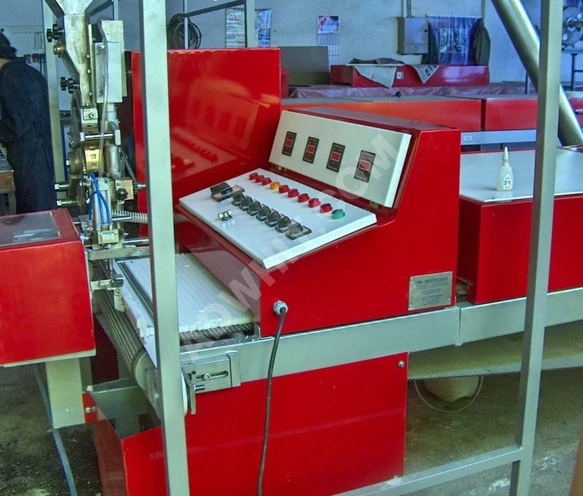

R TYPE CUBE SUGAR MACHINE

R-type facilities start with the input of raw granulated sugar and end with the output of packaged boxes.

Mixing and Moistening: Granulated sugar is mixed with a precisely dosed amount of water in a mixer, moistening it.

Drum (Pressing) Unit: The moistened sugar is filled into molds on a rotating drum. It is pressed under high pressure to take the shape of a cube.

Drying and Cooling: The wet cubes exiting the molds enter ovens (drying tunnels) on a stainless steel mesh belt. Then, they pass through cooling fans to be lowered to a temperature suitable for packaging.

Automatic Packaging (Robotic Filling): The sugars are placed into pre-prepared boxes by vacuum robotic arms without human contact.

Similar offers

Manufacturing and selling confectionery machines (Pishmaniye – Lokum – Halva – Chocolate)

0

TL

New

Manufacturer

Arifiye, Sakarya

2025/12/09

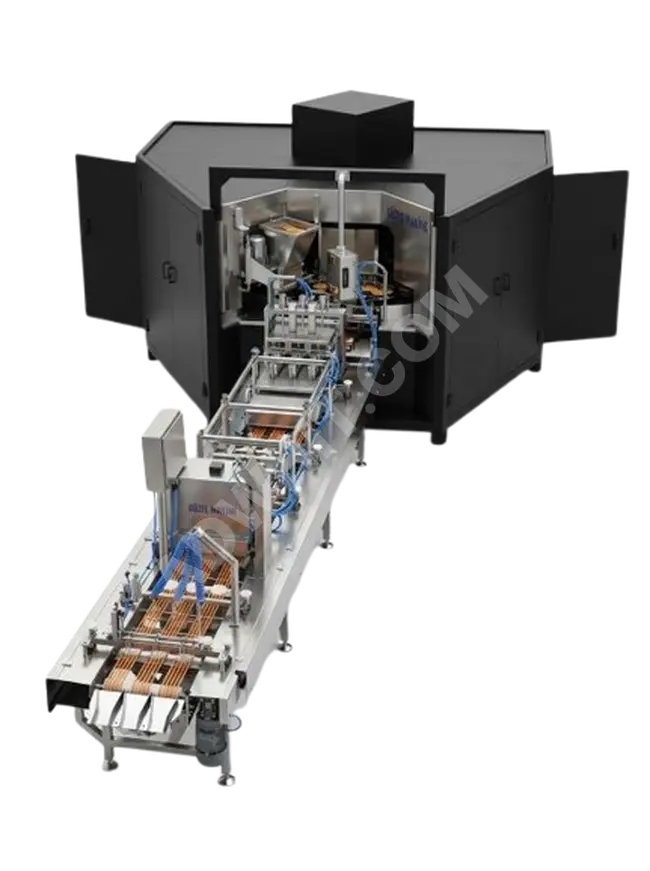

StroopWaffle-Belgium Waffle-Dutch Waffle Production Line

0

TL

New

Manufacturer

Merkez, Karaman

2025/12/30

Mayonnaise and ketchup production lines

500,000

TL

New

Manufacturer

Ümraniye, İstanbul

2025/12/12

Chips manufacturing machines

1

TL

New

Owner

Antakya, Hatay

2025/12/06

Potato chips manufacturing machines

1

TL

New

Owner

Antakya, Hatay

2025/12/06

Chips manufacturing machines

1

TL

New

Owner

Antakya, Hatay

2025/12/06