Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

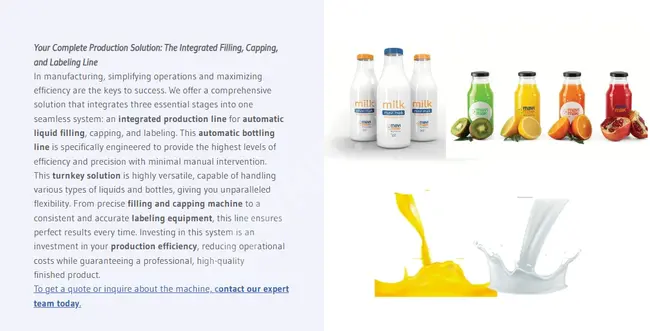

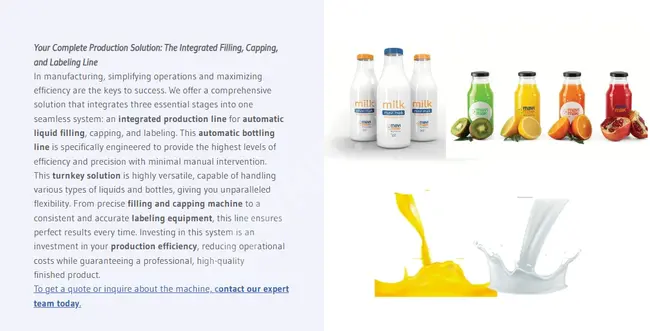

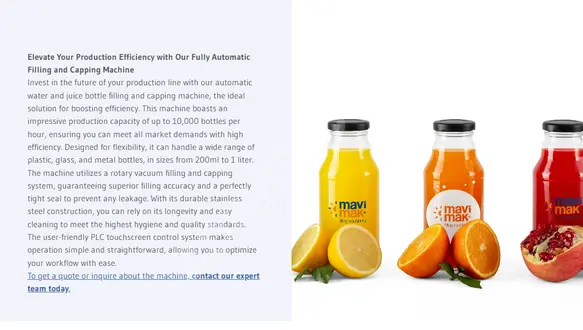

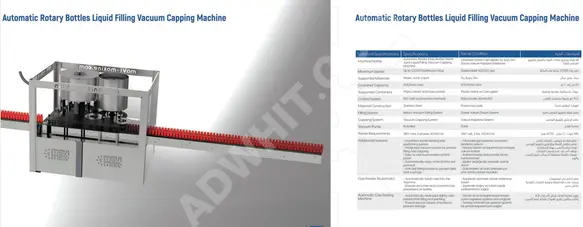

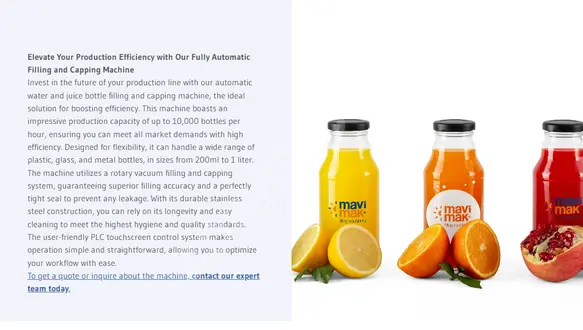

Automatic machine for filling liquids and vacuum capping

An advanced automatic machine designed for filling and sealing plastic, glass, and metal bottles for a wide range of liquids such as mineral water, juices, and beverages.

This machine features a high production capacity of up to 10,000 bottles/hour, making it the ideal solution for factories seeking to enhance efficiency and quickly and reliably meet market demands.

Thanks to the vacuum filling and capping system, the machine ensures precise filling and tight sealing that prevents any leakage and maintains product quality.

⚙️ Technical Specifications

Production Capacity: Up to 10,000 bottles/hour.

Filling Volume Range: From 200 ml to 1 liter.

Suitable Materials: Water, juices, liquid beverages.

Container Types: Plastic, glass, metal.

Control System: PLC with an easy-to-use touchscreen interface.

Manufacturing Material: Stainless steel for hygiene and durability.

Filling System: Rotary Vacuum Filling System (rotary filling system with vacuum).

Capping System: Vacuum Capping System (vacuum suction sealing).

Pump: Integrated within the system.

Power Requirements: 380 volts, 3 phase, 50/60 Hz.

✅ Additional Features

Automatic bottle feeding system with precise positioning.

Automatic stop in case of blockage or halt.

Anti-drip filling nozzles to reduce waste.

Automatic cap feeding and fitting system.

Hygienic and easy-to-clean design, compliant with food quality standards.

Suitable for high-demand water, juice, and beverage factories.