Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

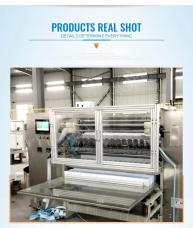

Baby Cleaning Cotton Baby Cotton Pad Machine

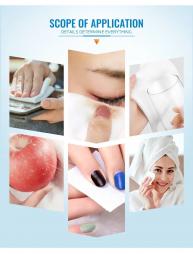

Makeup Pads Removing Machine ,Machine Material Steel Voltage 220V Power 4.5 Kw Weight 500 Kg Dimension 2500*1900*1600 Mm Pad Shape Round Or Customized Automatic Yes Application of Finished Products Makeup Pads/Puff Removing Application Scope Home/Beauty Etc. Available Pad Material Non-Woven Roll Pe+PP, Cotton Roll, Palace Roll Meat Speed 2000 Pieces/Min 8 Hours 9600 Pieces Accept Special Order Normal Diameter 50*60 Mm 70*80 Mm Or Customized Transport Package Carton Package Or Not Technical Specifications 2500* 1900 * 1600 Mm Hs Code 8451500000 Production Capacity

Round shaped cotton pads machine

1.the main working procedures of the machine: wrapping and transferring raw material, embossing in raw materials by heating system, punching raw materials to wrap around cotton pads, counting pieces, armors to get products, raw material collection etc. Moving elements such as to the retiree is done according to the customer's request.

2.The machine uses mechanical punching system, which includes 3 sets of round imported punching blades. It uses the most reasonable armoring method to make the waste of raw material to a minimum, which reduces the cost of finished products and improves production efficiency.

3.The main chassis of the machine is made of international quality steel and iron. It has 1 "steel reel to steel roller" embossing system with heating unit. You can make embossed round cotton pads or non-embossed round cotton pads.

4.The punching system has 3 sets of round fusing blades, raw materials imported from Japan to keep the punching system smooth and precise. There is no rough miss in the finished products.

5.The machine is equipped with 3 sets of tension adjustment systems and 1 set of raw material waste collection system.

6.The machine has automatic parts counting system designed by our factory. The width of the raw material rolls depends on the width of the punch die. The maximum diameter of the raw material rolls is approximately 100 cm.

7.The machine uses cam transmission system, equipped with 2 sets of specially wearable rubber conveying rollers and other parts, and uses aluminum alloy rollers to transfer raw materials. The machine uses vertical output path.

8.The machine uses frequency converter (converter) to control the production speed. The wiring layout of electrical parts is reasonable. The machine makes a slight operating noise and is easy to operate.