Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

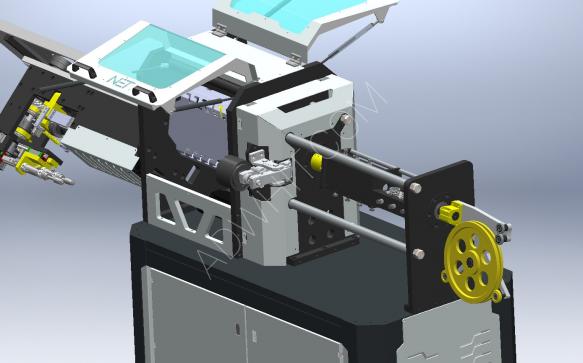

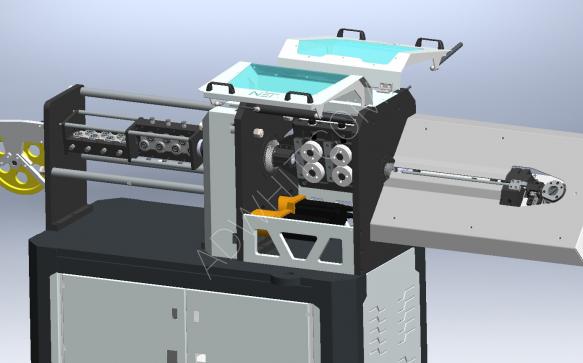

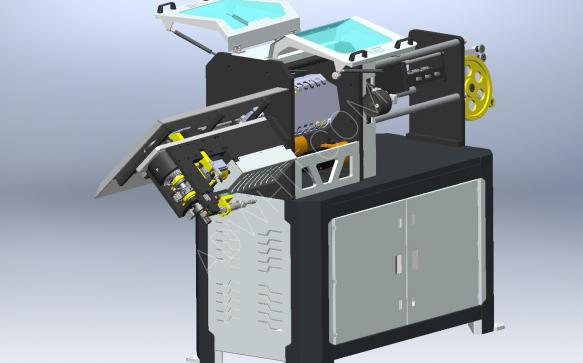

3D CNC WIRE BENDING MACHINE

PROJECT DESCRIPTION

It is the ideal solution partner that can be preferred in the manufacturing of Automobile Seat Components, Wire Chairs, Wire Bathroom and Kitchen Accessories, and White Goods Components.

You can twist Ø2.5mm – Ø8mm thick wire as you wish.

Maximum wire feeding speed of 75 m/min

0.05 degree bending precision

Precise Height Measurement with Encoder Integration

7+7 Bidirectional Wire Straightening System

M-Code Definition According to User Request

Windows Based and User-Friendly PC Interface Design

Remote Technical Support and Assistance

Creating Error and Warning Reports

Running the Job List by Turning the Handwheel

Stepping through a Worklist Line by Line

It produces your products and/or parts that you design in different sizes and different wire diameters under serial conditions with CNC Programming technique.

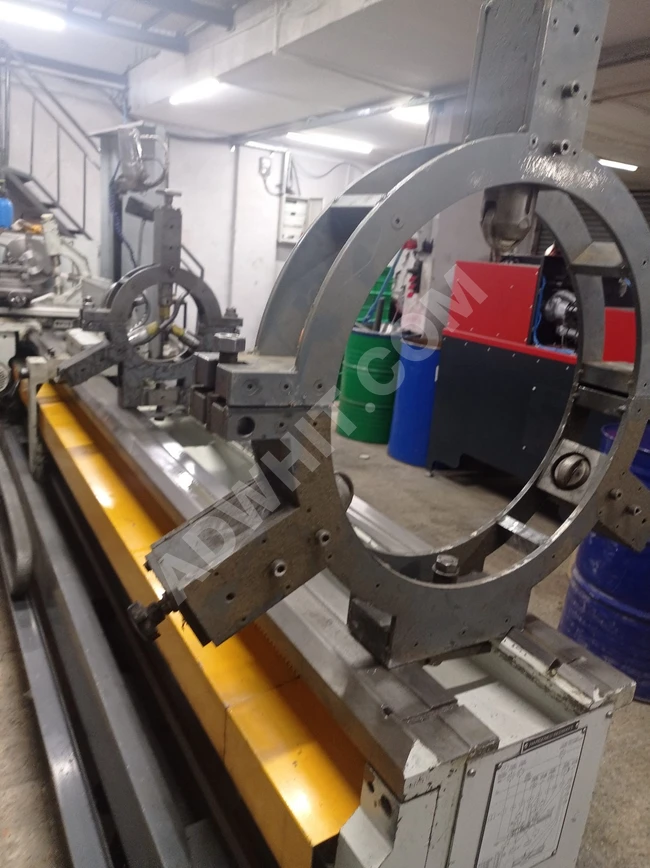

There is a wire loading unit that is integrated with the machine and operates automatically, with a maximum load carrying capacity of 1500Kg. Rotational movement is provided by a helical gear reducer coupled to a 1.5kW asynchronous motor. The load inverter used for the asynchronous motor is Mitsubishi brand. The straightness of the wire to be bent is adjusted manually with the straightening bearings on the machine, which are positioned in 7 Horizontal Positions + 7 Vertical Positions and have a V-shaped channel around them.

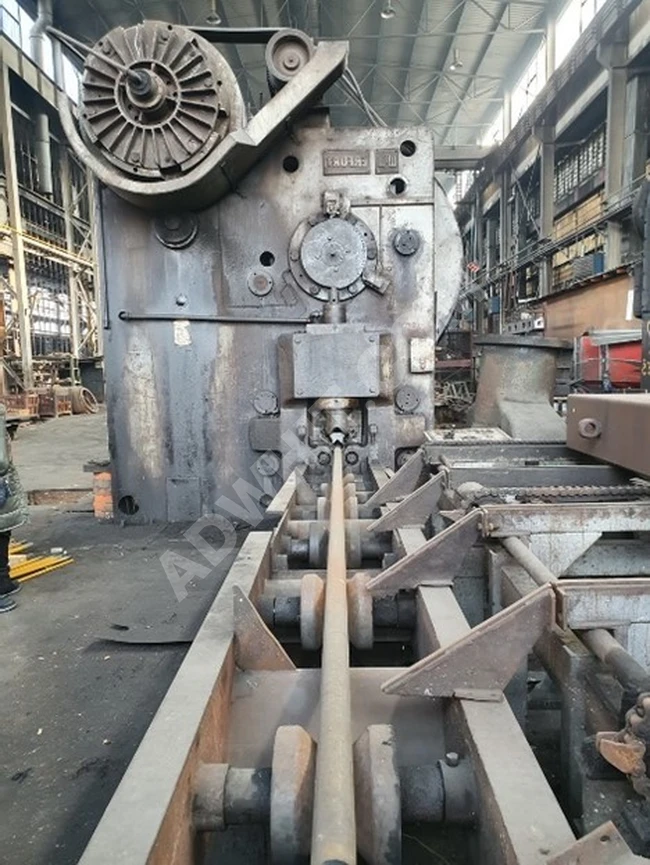

The definition of the third dimension of the products and/or wire parts is achieved by moving the wire in the direction of the specified value, axially unlimited 360° clockwise and/or counterclockwise around a fixed console. This technology is used in many machines for the production of spring wire bending.

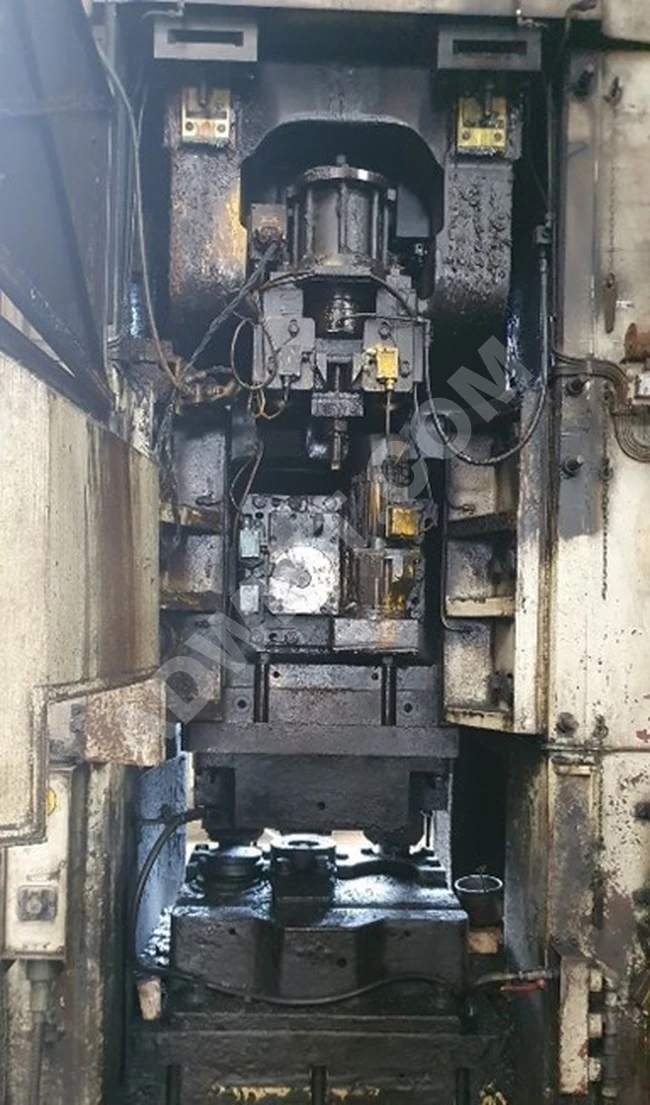

It is more suitable than many machines of European origin for the use of wire raw material produced in domestic factories – thanks to the “floating” mobility of the wire straightening unit (i.e. the wire does not repeatedly pass through the straightening unit when moving backwards) and the presence of notched screws for more precise adjustment of the position of the straightening bearings, allowing adjustment of linearity makes it easier.