Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Self Employed

Job Listings

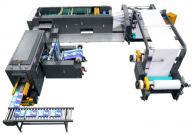

ALM-A4 Paper Production Line and Packaging Line

Advantages

2.1. Equipment techniques

We explain the functions and work flow related to paper products as technology of our machine: opening → cutting → conveying → assembling → packing.

A.1. Main technical parameters

A.2. Standard configuration

1. Jaw holder (1 set = 2 rolls)

Type A-1: CHM-A4-2

1) Machine type:

2 sets of pivotless paper shelves can be placed on each machine table.

2) Paper roll diameter:

maximum. Ф1400mm

3) Paper roll width:

maximum. Ф850mm

4) Paper rack material:

solid

5) Clutch device:

Air brake and control

6) Clutch lever adjustment

Manual adjustment according to hydraulic pressure

7) Difficulty of paper core

3" (76.2 mm) air expansion

Axis mirror

2. Automatic tension control system

Type A-2: Automatic tension control system

1) When the paper passes through the sensor, automatic feedback is provided to the PLC control system to increase the brake load, and increase or decrease the tension to automatically control the paper tension.

3 High precision cutting blade system

Type A-3: High precision cutting blade system

1) Since the upper and lower blades are rotary, the cutting accuracy is very high.

2) The anti-bend device includes one set of square rail and steel wheel. Of paper edge unit which can adjust and level the paper square.

3) 5 sets of slitting blades

The top of the slitting blade is done by air pressure and spring.

The lower blade, connected to the bearing motor (diameter is Ф180mm) and moved by spring. The upper and lower circular blade are made of SKH. The lower blade of the slotter (diameter is Ф202 mm) and driven by belts at the same stage. The lower slit blade consists of 5 groups, each group has two blade edges.

Paper width:

Gross width 850mm, net width 840mm

the number of pieces:

2 pieces - A4 210mm (width)

Paper roll diameter:

Max.Ф1400mm. Minimum Ф600mm

Paper core diameter:

3 inch (76.2mm) or 6 inch (152.4mm) or as per customer's request

Wrapping paper quality:

High quality copy paper; High quality office paper; High quality tree free paper etc.

Paper weight:

60-100 g/m²

Page length:

297mm (specially designed for A4 paper, cutting length 297mm)

Bulk Quantity:

500 pages maximum. Height: 45-55 mm

Production speed:

Maximum 0-250m/min (depending on paper quality)

Maximum number of pieces:

Max 841/min

Bulk output:

Max 12 rolls/min

Cutting load: 100 g/m² (1×100 g/m²)

Cutting accuracy:

±0.2mm

Paper cutting requirements:

No speed change, no breaks, cut the whole sheet in one go and you need the right sheet.

Main power supply:

3*380V/50Hz

Enter:

220V AC/24V DC

power:

22 kW

Air consumption:

200 nl/min

Pressure:

6 sticks

edge:

5~15mm*2

Safety standards:

Design according to safety standards

4) Paper feeding wheel

Top wheel:

Ф200*550mm (rubber coated)

Bottom wheel:

Ф400*550mm (anti-slip)

5) Cutting blade set

Upper cutting blade:

1 piece 550mm

Bottom cutting blade:

1 piece 550mm

6) Driving set (bear motor and high precision belt)

7) Main drive motor set: 15KW

4. Transportation system

A-4.Type: Conveyor system

1) Transport with flat and telescopic device

2) High-speed conveyor belt and pressure wheel. Printing paper compatible with upper and lower conveyor belt, automatic tightening and closing system.

3) Fixed removal device (fixed removal rod included)

and negative ion generator)

5. Paper collection system

A-5 Type: Paper collection system

1) An automatic device that moves the stack of paper up and down

2) The treadmill and clapboard are organized. Control with air tank,

When it is design paper, the cylindrical strip of paper is cut and moved up and down.

After transferring the paper to the tape, carry it diagonally to the laminating table.

6. Accessories

A-6 Type: Accessories

Cross blade

:

1 set 550mm Material: Tungsten steel composition

(including lower blade and upper blade)

Top cutting blade

5pcs Ф150mm Material: SKH

Bottom cutting blade

:

5pcs Ф202mm Material: SKH